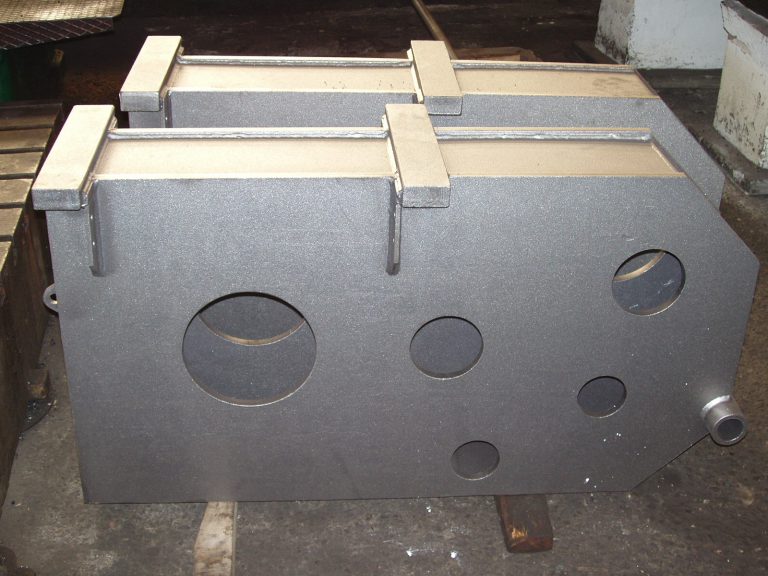

Steel structures, production of frames, body frames, chassis, booms,pedestals, parts for crane, marine, offshore, blocks for rope, winches, lars frames, skids; mining, construction, offshore, production of military vehicle, rail vehicles and their components - CL1 certification level, welding of steel load-bearing structural elements - in classes EXC1, EXC2, EXC3.

Parameters:

Material groups: 1.1, 1.2, 1.3, 2.1, 3.1, 8.1 / carbon steels, thermo-mechanically processed steels, thermally improved steels, stainless steels. Welding methods:

Cutting